Manufacturers agents, stockists and suppliers of high quality

Heat exchanger/boiler tubes to the process industries.

Call us on: 07590 996953

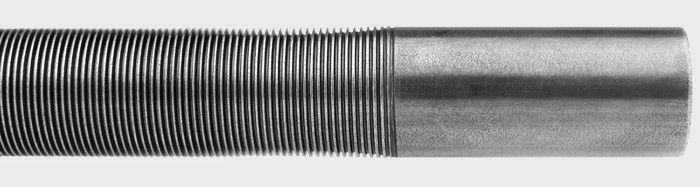

Integrally Finned Tubes

Integrally finned tubes, supplied by Heat Ex Tube Limited, are ideal for industries that need to increase the heat transfer performance of fluids, whilst minimising the physical size and cost of heat exchangers.

Most tubular materials can be finned. However, the hardness of the material determines the finning code or fin profile.

The fin itself is rolled out from the wall of the tube - making it integral with the tube. By rolling the fin, the wall thickness beneath the finned section is reduced compared with the plain ends.

Harder materials like stainless steel, nickel alloys and titanium have greater fin density (28, 30 or 36 fins/inch). The shallower fins reduce work hardening of the material - eliminating the risk of the fin root cracking. Softer materials such as carbon steel, copper and copper alloys have a deeper fin profile which gives them a lower fin density (16 or 19 fins/inch).

Using integrally low finned tubes can massively improve the typical surface area by:

- 19.5mm OD with 19 fins/inch = 270%

- 25.4mm OD with 26 fins/inch = 330%

The % increase depends on the fluids within the heat exchanger and thermal performance improvement varies from 20% to 100%.

Manufacturing limitations:

- Carbon and low alloy steel

- Stainless steel: TP304 / TP304L / TP316 / TP316L / TP321 and duplex

- Copper alloys: 443 / 687 / 706 / 715

- Titanium and high nickel alloys

- Tubes with an outside diameter of 12.7 / 15.8 / 19.05 and 25.4mm

- Plain end wall thickness: >1.25mm

- Tube lengths up to 24,000mm

Get a quote for integrally finned tubes

At Heat Ex Tube Limited, we can customise integrally finned tubes to match your unique requirements. All tubes are manufactured to the highest quality and are priced suitably for every budget, offering exceptional value for money

If you require u bent integrally finned tubes, plain ends or intermediary unfinned sections, please specify.

For more information or to discuss your needs in more detail feel free to call us on to 07590 996953.

Order integrally finned tubes

If you’re happy with the quote we provided for integrally finned tubes, all that’s left to do is place your order by emailing us at tubesales@heatextube.co.uk.

Fast, efficient delivery of integrally finned tubes

We make sure all integrally finned tubes are delivered on time, regardless of destination, and can schedule delivery to meet emergency or planned maintenance requirements.

In a rush? If you need your products sooner, take advantage of our emergency delivery service.